Stainless steel is an alloy resistant to rusting and corrosion. It originated in 1798 and has been applied to architecture since the early 1900s. Its elements include C, Ni, Ti, Mn, N, Nb, Mo, Si, and Cu. Among them, Cr is the main characteristic determining stainless steel corrosion resistance, which will form a coat of self-passivation (oxide) film on the surface to prevent corrosion.

Types of stainless steel include austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steel. The most commonly used types of stainless steel are 201, 304, 316L, and 430 worldwide. You can choose it according to the environment. When used for city architecture, 304 is the best performance and cost choice.

As decorative materials, stainless steel supports various processing, including brushed, polished, colored, and embossed. Different situations need different stainless steel finishes. An embossed finish may be chosen in high-traffic areas for its higher scratch resistance.

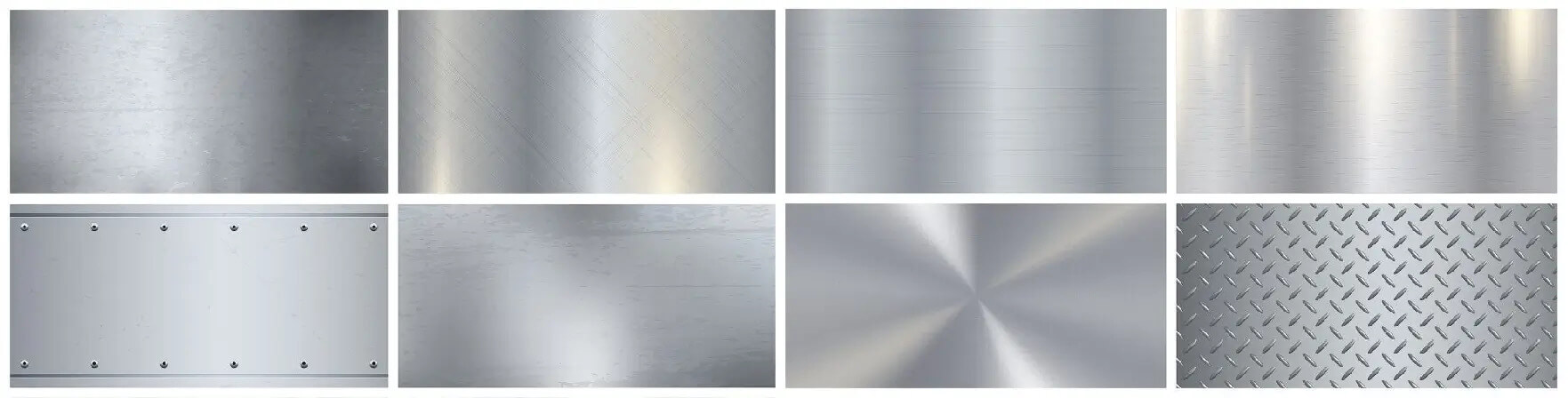

Stainless steel’s original surface is hot-rolled steel (No. 1), characterised by a rough, matte finish and a black oxide scale. Through pickling, cold rolling, and polishing, these raw materials are transformed into high-value decorative sheets. During the deep processing, each process will create a surface texture, and some common stainless steel surface treatments include polishing, brushing, and sandblasting.

Mirror Finish Stainless Steel

Typically, the most popular surface is mirror polishing, including 6K, 7K, 8K(Super Mirror), and 10K. Its roughness is less than 0.8 μm. By mirror polishing, the luminosity of stainless steel can be maximized to achieve a sparkling, mirror-like finish. Usually, the wear marks of the mirror finish are barely visible.

A creative method of polishing mirrors is the water mill, which involves three polishing steps and three washing steps. During processing, the smoothness of the surface and the flatness of materials can be adjusted. Due to its superfinish, which can prevent bacterial growth, mirror sheet is the best choice for the medical and food industry.

The mirror finish stainless steel is often applied to product frames, interior wall decoration, landmark buildings, fittings, bathroom mirrors, and ornaments. The stainless steel thickness and the project details will affect the quality of the mirror finishes. So, you must confirm the specification as per your project requirements. If you can not make a selection, please consult with TOPSON and obtain professional suggestions from our engineers.

Bead Blasted Stainless Steel

Bead blasting is a finish that utilises the bead blaster, shooting the bead-shaped media to the stainless steel surface at high pressure. The process is often performed using abrasive blast cabinets, which typically use compressed air to accelerate the media. Generally, this process maintains the metallic properties of stainless steel and leaves a smooth, shiny, and cleaner matte surface.

The bead blasted finish depends on the blast media size. The blasted surface will appear bright and have a matte texture when using finer grades. And the coarser bead will produce a uniform surface, but rougher. The media used in bead blasting are glass beads, steel shot, aluminium oxide, and plastic media. At Topson, the first medium is glass beads.

Due to its excellent surface finish, bead-blasted stainless steel sheet is suitable for various industries, including construction, elevators, ornaments, ceilings, and perimeter applications. It could be adjusted as required for the project.

Water Ripple Stainless Steel

A water ripple sheet is a decorative stainless steel that utilizes embossing to form a water texture on the surface. The size of the rippling could be adjusted as required for the project. The most commonly sought classification of sizes is tiny, medium, and large.

When used in decorating, it can reflect the surrounding scenery in a subtle way and brings spaces a dazzling, vivid, and luxurious ambiance.

Water Ripple has stronger corrosion resistance and a higher aesthetic. It can be applied to decorating the ceiling, elevator door, hallways, architectural wall cladding, etc. Generally, 304 stainless and 316 stainless steel are available to fabricate water ripple.

Combined with the Mirror(8K), hairline finish, or PVD coating finish, this technique enables to create of unevenness on both sides of the surface (respectively).

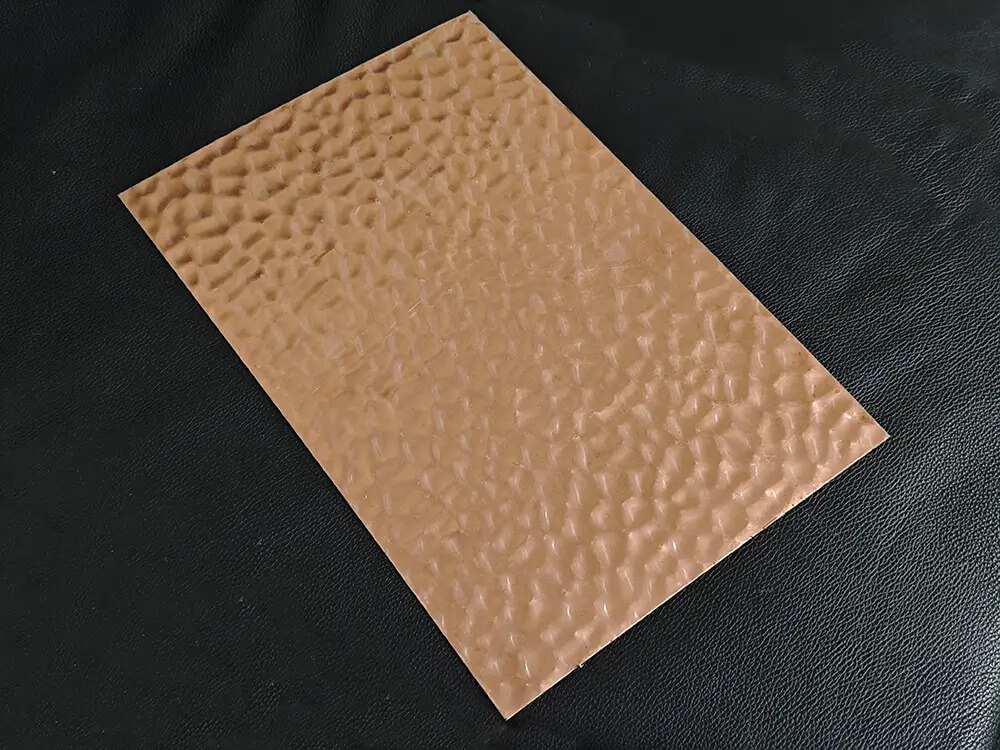

Hammered Stainless Steel

Hammered stainless steel is characterized by a dimpled, textured surface created through controlled hammering. This process enhances both its aesthetic and functional properties, making it popular in architecture, design, and kitchenware. Hammered can be based on a mirror sheet or others with a matte finish.

Processing methods of hammered stainless steel include hand hammering and mechanical hammering. The hand hammering request is to heat the sheets to 790–845°C to soften.

Hairline Stainless Steel

Hairline finish is one metalworking type of brushed finishes. It forms a matte surface on the stainless steel panel with long, continuous and uni-directional grind marks. It is referred to #4 finish stainless steel sheet. But it is more reflective than a No. 4 polish.

Adjusting the grinding technology can control the texture size to create different brushed effects, like D-HL and Scratch HL. TOPSON will help you achieve whatever brushed finish you need with our strong metalworking.

As one of the classics for stainless steel, hairline finish stainless steel is suitable for interior and exterior products, such as elevator door, escalator cladding, architectural decoration, kitchen cabinet and so on.

Brushed Stainless Steel

Cross hairline or cross brushed, is a stainless steel brushed finish with a pattern of intersecting lines at a 45-degree angle.

The grain size can be adjusted by controlling grinding times. Prior to specification, confirm the texture direction with your metalworking fabricator based on project requirements.

Cross hairline is the most commonly sought decorative finish of stainless steel. Due to its excellent scratch resistance, it is suitable for high-traffic areas, like construction cladding, elevator handrails, ornaments, and perimeters.

Vibration Stainless Steel

Unlike hairline finish, vibration stainless steel is a low reflective brushed finish with short, non-directional arch-like grind marks. It utilizes vibratory polishing technology, and the vibratory action causes the media to rub against the workpieces to generate the desired result.

Vibration is the second most commonly sought stainless steel finish as a decorative material. With higher corrosion resistance and scratch resistance, it suits for panels and handrails.

Another advantage of vibration stainless steel, it supports further processes, such as PVD colored or plating, for higher aesthetics and scratch resistance. If so, it may be the best choice for exterior products in high-traffic areas, like architectural walls, luxury doors, advertising boxes, outdoor screens, etc.

Satin Stainless Steel

Satin stainless steel, also known as brushed stainless steel, is a type of stainless steel that has a distinctive matte finish. It is created by brushing the metal surface with a fine abrasive material, which produces a consistent pattern of fine and discontinuous lines or scratches on the surface.

Satin stainless steel has several properties, making it a popular choice for various applications. First, it is highly resistant to corrosion and rust, making it ideal for use in environments where moisture and environmental exposure are concerns. Additionally, it is durable and easy to clean, making it a low-maintenance option for a variety of uses.

Another critical property of satin finish stainless steel is its aesthetic appeal. The matte finish of the metal gives it a modern and sleek look often used in contemporary architecture. It also has a subtle texture that can add depth and interest to surfaces and objects.

Satin stainless steel is commonly used in producing appliances, kitchenware, and other household items due to its durability and resistance to staining and scratches. At that time, it also can be used in the construction industry for building facades, handrails, and other architectural elements.

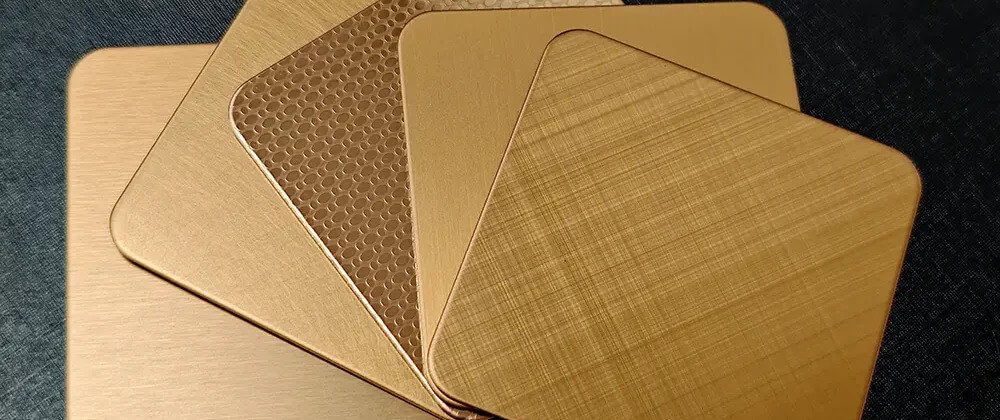

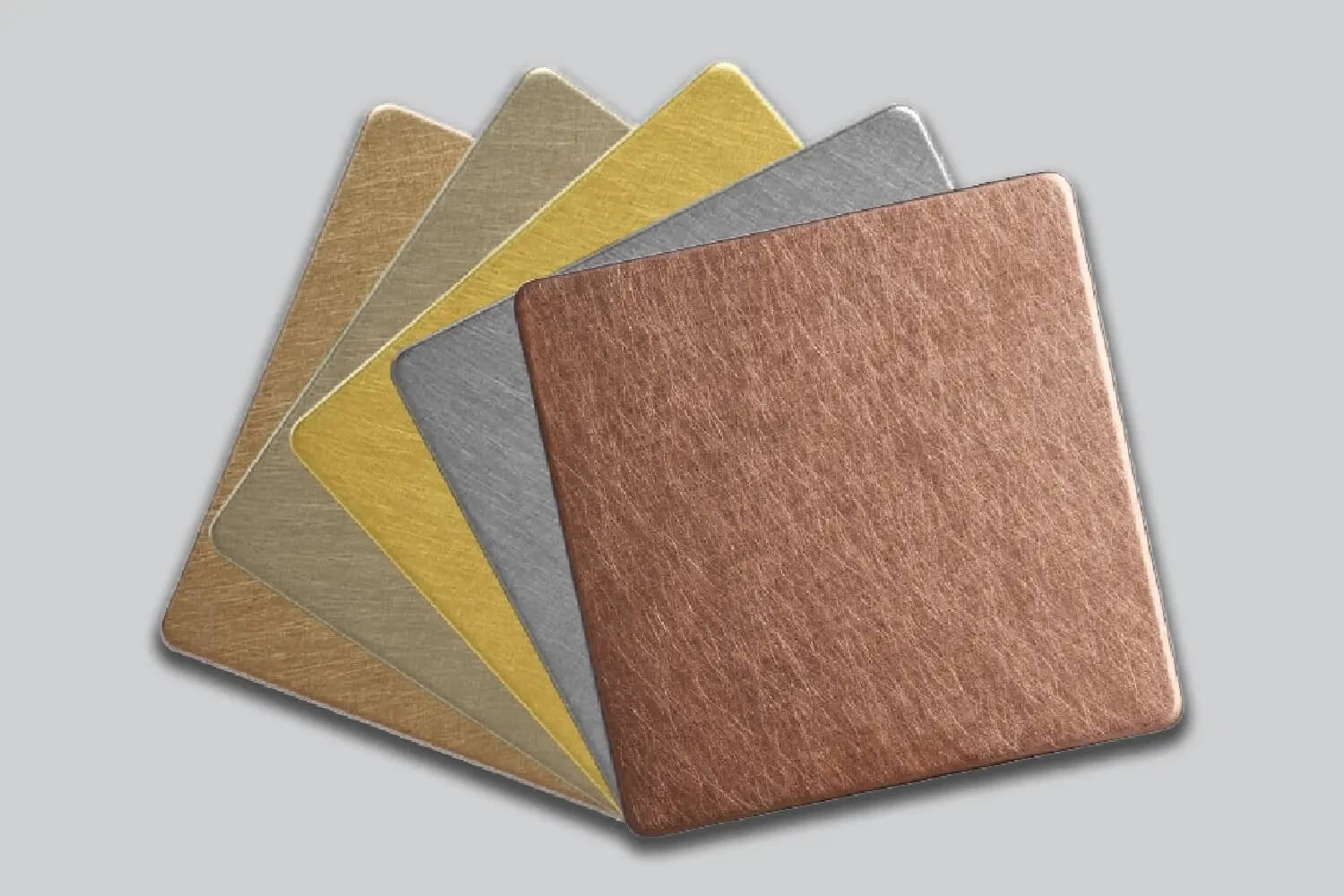

PVD Coating Stainless Steel

PVD coating, also known as thin-film coating, is a process that utilizes physical technology to vaporize the solid material in the vacuum environment and deposit it onto the stainless steel surface. The vaporized materials exit in the form of atoms.

By PVD finishing, stainless steel panels can achieve to fusing various color to enhance its beauty. Colors you can obtain including silver, gold, rose gold, bronze, brass, LIC black, antique copper and so on.

Due to its strong sense of aesthetic It is highly regards in architecture and product decorations for a luxurious ambiance, as well as elevator, screen, ceiling, cladding, and panels.

Embossed Stainless Steel

Embossed stainless steel is a type of stainless steel stamped or pressed with a pattern or design. This gives the metal a 3D texture that can add visual interest and depth to surfaces and objects.

Embossed stainless steel has many of the same properties as regular stainless steel, including high resistance to corrosion and rust, durability, and ease of maintenance. The embossing process does not affect the metal’s strength or integrity but enhances its scratch resistance and creativity, making it a reliable choice for various applications.

With its excellent properties, embossed stainless steel is commonly used to produce decorative elements, such as backsplashes, wall panels, and furniture accents. You also can use it for signage, nameplates, and other branding applications.

Besides stainless steel, other metals like aluminum and copper also can be stamped or pressed with texture. If you want to purchase embossed metal, do not hesitate to contact TOPSON!

Acid Etching Stainless Steel

Acid-etched stainless steel is another type of stainless steel surface treated with an acid solution to create a textured or patterned surface. The acid etching process removes part of the thin layer of the metal, creating a matte finish with a subtle texture.

One of the key advantages of acid-etched stainless steel is its versatility. It can be used for decorative elements, architectural features, and branding applications. The texture created by the acid etching process can also help improve the surface grip, making it a popular choice for handrails and other safety features.

Acid-etched stainless steel also has a unique appearance that can add visual interest and depth to surfaces and objects. It also has many properties as regular stainless steel, including high resistance to corrosion and rust, durability, and ease of maintenance.

Overall, acid-etched stainless steel is a durable, low-maintenance material with a distinctive appearance that can be customized to suit a wide range of applications.