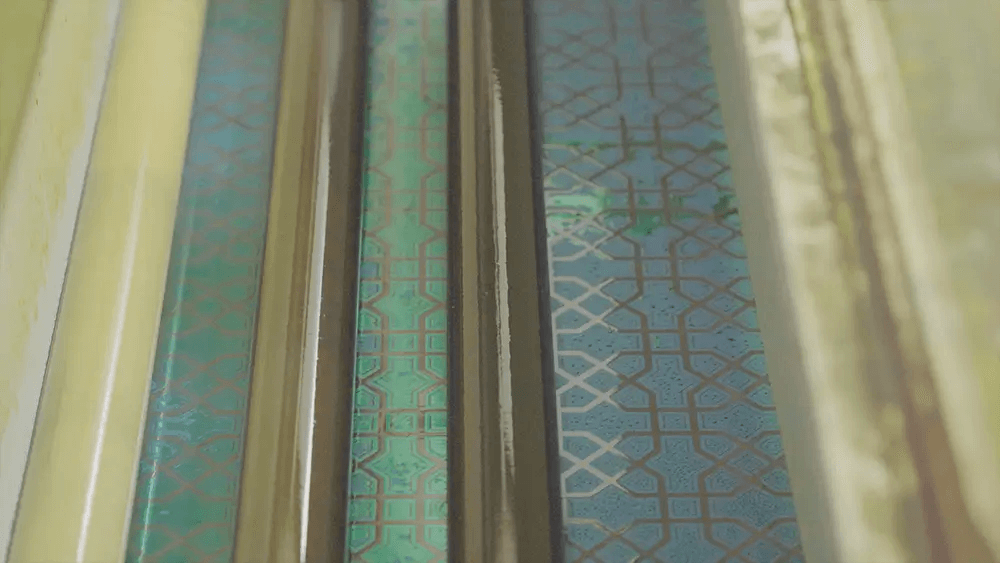

Etched metal is a standard material used in architecture, signage, and elevator design. While taking elevators, you will notice that the doors or cladding feature beautiful and intricate patterns. These patterns are achieved through chemical etching, also known as acid etching. This article will introduce what acid etching is and its benefits when applied to metal.

What Is Acid Etching

Acid etching is a subtractive manufacturing process that utilizes temperature-regulated chemicals to remove excess material from the surface, thereby creating a desired pattern. Unlike laser etching, acid etching is a low-cost and efficient process suitable for deep processing of stainless steel sheets to create complex patterns. The depth of the etching patterns ranges from 0.1mm to 1.0mm. It is essential to note that acid etching is not suitable for creating local patterns or precise parts.

What Does Acid Etching Do to Metal

Acid etching is a controlled corrosion process that uses acid to selectively remove metal from a surface. We can say “dissolving” parts of the metal to create a desired effect.

1. Acid etching physically and visually changes the metal

The etched areas become slightly recessed. You can feel the texture and depth with your finger. Unlike an embossed pattern, an etched pattern is coherent and whole. For decorative or marking purposes, the etching depth is very shallow (often 0.1-1.0 mm), so it does not compromise the overall properties of the metal.

2. Acid etching enhances the properties of the metal

Surface treatment can enhance the aesthetic and properties of materials. For example, embossing changes the strength of metal; mirror polishing improves the reflectivity of the metal surface. Acid etching can also enhance the surface properties and functionality of the metal. But it does not make the metal itself stronger or more durable throughout its entire structure.

Here is a breakdown of the properties that acid etching genuinely enhances:

1. Enhanced Adhesion

By creating a microscopically rough surface, acid etching dramatically increases the surface area for coatings to grip onto, especially in powders.

2. Enhanced Aesthetic

Acid etching transforms the visual and tactile qualities of the metal. It can create a beautiful, non-reflective matte finish that hides fingerprints and minor scratches, which is highly desirable for architectural panels.

3. Enhanced Lubricity (Oil Retention)

The tiny grooves and pores created by etching can trap lubricating oils, allowing them to remain in place.

4. Enhanced “Grip” or Tactile Feel

The textured surface provides more friction, which can be a functional enhancement.

There is a critical point. For stainless steel, the passive oxide layer that provides corrosion resistance is removed in the etched areas. Therefore, a protective coating is often applied after etching to restore corrosion resistance.

Method to Achieve Acid Etched Stainless Steel Finish

Here is a detailed look at each step involved in chemical etching.

1. Material Selection: The first step is to choose the right size of materials. Standard sizes of Topson stainless steel sheets are 1000 mm × 2000 mm, 1219 mm × 2438 mm, and 1500 mm × 3000 mm. Thicknesses range from 0.40 mm to 3.0 mm.

2. Pre-Clean: Once the material has been selected, it undergoes a rigorous cleaning process. This includes removing debris, wax, and mill oils that could interfere with the chemical etching process.

3. Lamination: Once cleaned, a light-sensitive photoresist is laminated onto the metal plate, excluding any areas that require protection. This step is crucial to the accuracy of the finished product.

4. Printing: A photoresist mask containing the desired design is prepared, and the laminated metal sheets are exposed to ultraviolet (UV) light.

5. Developing: The sheet is developed to remove the unexposed photoresist, revealing the original metal to be etched.

6. Etching: Chemical etching agents, commonly using ferric chloride, are applied to the prepared metal sheet.

7. Stripping: After etching, the remaining photoresist is stripped away, unveiling the finely etched components.

8. Inspection: Finally, each component is rigorously inspected using advanced optical inspection equipment to ensure it meets the expected specifications.

Get Chemical Etched Stainless Steel from Topson

At Topson, we take great pride in our ability to craft a variety of high-quality, chemically etched stainless steel sheets tailored to your unique needs. We utilize the latest chemical etching technology to produce intricate designs with unparalleled precision, including silkscreen and photosensitive applications. Available grades include SS 201, SS 304, SS 316, and SS 430.