Working on decorative panels or sheets, as well as in component engineering, the selected etching technique defines both the aesthetics and performance. Techniques of etching, such as dry etching, wet etching, and acid etching, are a significant part of many industries like electronics and architecture. For companies in need of precise and delicate surface finishing and elaborate motifs on stainless steel, this knowledge is essential.

In this article, we shall deconstruct the difference between dry etching and wet etching, and thereby we shall discover why acid etching, a wet etching method, will be beneficial in its own very special way, particularly when it comes to stainless steel. We shall also highlight how Topson Metal offers unique etched metal solutions, both decorative and practical, that enhance.

What is Dry Etching

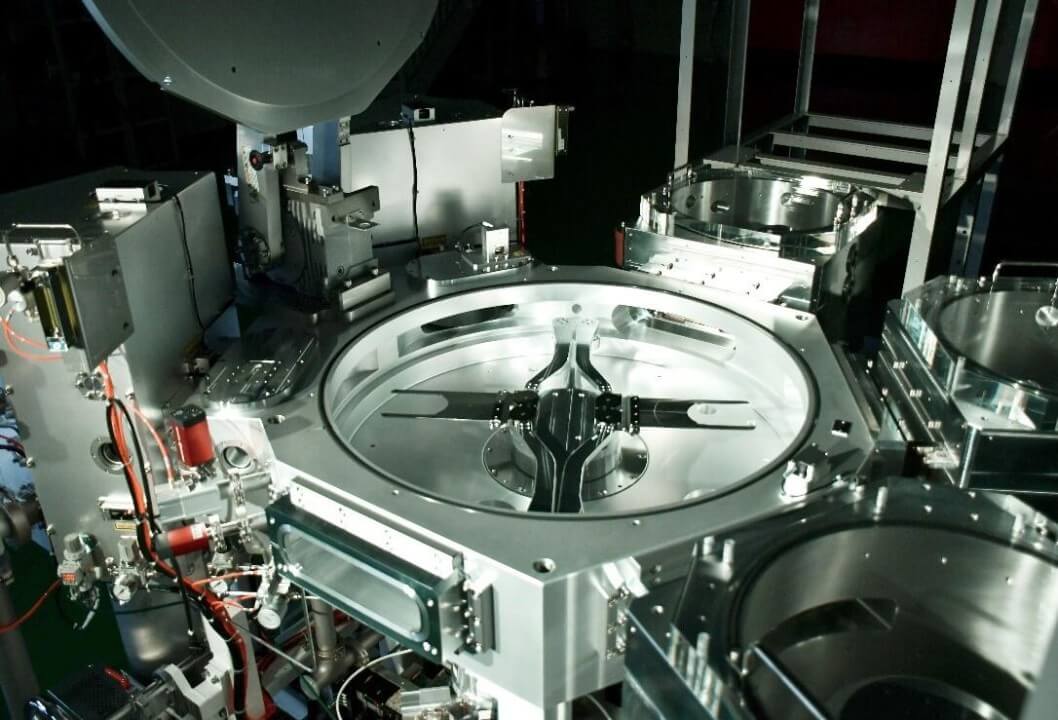

A subtractive technique uses a gas or plasma to etch away part of the surface of a metal or semiconductor; it is known as dry etching. It is mainly applied in industries that involve high precision micromachining, also known as the microelectronics industry and nanotechnology. Unlike wet etching, which uses liquid chemicals, dry etching is generally directional or anisotropic, meaning it etches primarily in one direction (often vertically), allowing for precise control over the shape of the etched features.

Common Dry Etching Methods:

● Reactive Ion Etching (RIE): Chemically reactive plasma is used to etch fine features.

● Ion Beam Etching: It implements directed ion beams to transfer a pattern.

● Plasma Etching: A surface of fineness made up of low-pressure plasma.

The advantage of dry etching is that it is anisotropic, i.e., it preferentially etches in one direction (usually vertical), so that well-defined and sharp patterns can be obtained and undercutting is avoided. This property is beneficial in such applications as semiconductor fabrication, where accuracy and cleanliness must be maintained.

Dry etching is widely applied in fields requiring precise material removal, particularly semiconductor manufacturing, micromachining, and display production.

What is Wet Etching

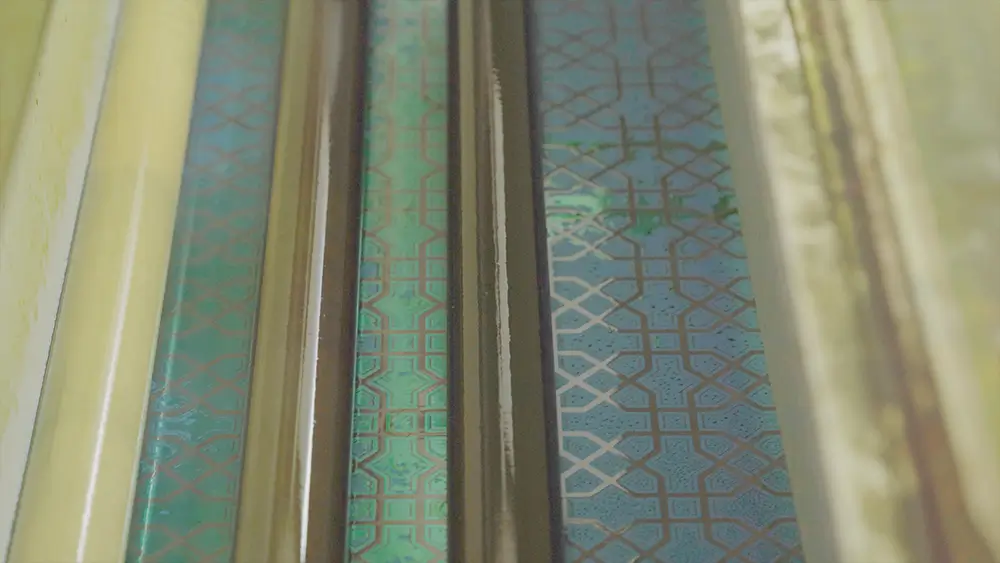

In contrast to the dry processes, wet etching uses liquid chemical solutions to remove the unwanted material on the surface of a metal. It is one of the most widely used etching methods as it is easy, cheap, and flexible. Wet etching is commonly used on stainless steel surface treatment to achieve complex textures, but it is not suitable for handling micron-sized patterns.

Wet etching finds special application in large areas and ornamental finishes. It is isotropic (etching everywhere) or anisotropic, with the choice of material and chemistry. In stainless steel surface treatment, wet etching includes silkscreen and photosensitive processes. The etching depth of the former is 0.10mm, and the latter is 1.00mm.

Steps to Wet Etching

● Confirm the etching pattern

● Prepare the etching solution

● Paint protective oil to cover those areas that are not to be etched.

● Etching on the machine (acid or alkaline solution)

● Cleaning, drying, and covering with PVC film

The exposure of the metal leads to its dissolution by the chemical reaction with the etchant, which creates the intended pattern or design. Acid etching is a common type of wet etching, and we will look at this process closely below.

Differences between Dry and Wet Etching

By understanding the distinction between wet and dry etching, designers and manufacturers can make informed choices about the technique, considering factors such as material, cost, environmental impact, and accuracy requirements. Dry etching is more precise but limited to smaller areas. In contrast, wet etching, and therefore acid etching, is used on stainless steel works of art, such as panels, signs, and architecturally used metal. For more differences between dry and wet etching, please refer to the picture below.

dry etching vs wet etching

Topson Stainless Steel provides etched stainless steel sheets at the highest levels with wet and acid etching processes to make decorative patterns that are quite suitable in elevators, hotels, and public art objects.

Is It Acid Etching Wet Etching

Acid etching is a form of wet etching. Acetic chemical solutions are used to corrode the material (typically the surface of a metal) and remove it. Etchants such as hydrochloric acid, nitric acid, or ferric chloride are most often employed, and they vary with the types of metal to treat.

In stainless steel, in the case, acid etching enables:

● High-pressure measured infiltration into the surface

● Strong decoration patterns

● Better adhesion than paints or coatings

● Anti-glare finishes matte

Acid etching is a very popular tool in architectural/design uses. It is also the mode through which Topson Stainless Steel can give the world a luxury finish to its worldwide projects, such as hotels, malls, and other high-end residential designs.

Advantages of Acid Etching

Stainless steel consists of a durable, non-corrosive, and visually appealing material that is challenging to work with without a proper process. It is here that acid etching excels. The following are some of the advantages of acid etching stainless steel products to be considered, particularly when dealing with ornamental or architectural panels:

Increased Beautifulness

High definition on stainless steel is achieved through acid etching, which is ideal to be used on interior panels, signage, elevator doors and cladding. The patterns may be geometric, flowered, text-related or in the form of art. Topson Stainless Steel offers a custom acid-etched product that is both elegant and durable, providing the proper combination of beauty and strength.

Surface Integrity – Long-lasting

As opposed to surface painting or printing, acid etching is indestructible; it cannot be worn off or peeled. The acid-etching step makes the acid-cut part an inseparable bit of metal. This is a significant advantage when it comes to long-term installations.

Better Adhesion

Stainless surfaces that are etched provide additional adhesion to coating, laminate or paint. This causes them to become an adequate foundation for multilayer designs or hybrid materials.

Anti-fingerprint finish and Matte combinations are available.

Acid etching may also reduce the shiny surface of stainless steel, making it less fingerprint- and glare-resistant, which is appropriate in places open to the general population or areas of high-indexed contacts.

Large Surface Cost-Effective

Compared to dry etching, which is expensive and typically limited to small-scale operations, acid etching is a more cost-effective and efficient method for working on large sheets of panels. This will make it ideal for cladding and interior design works.

Topson Stainless Steel offers the finest acid-etched stainless steel sheets, providing a unique combination of beauty, precision, and reliability. These are designed for their solutions.

Architectural applications

● Fancy interior design

● Functional signage

● Elevator and lobby designs

Having a roster of skilled designers and fabricators at its command, Topson makes sure that every sheet of etched metal exceeds the international criteria of quality yet still possesses the eloquence of style. To provide a complete package of metal surface treatments to clients, they offer custom etching, PVD colour coating, and laser cutting.

Look at their etched sheet collection here and bring your vision to life.

Conclusion

The various forms used in the etching differ in terms of dry etching, wet etching, and acid etching, depending on what your priorities are: precision, cost, durability, and aesthetic. Dry etching can be very precise at the micro scale. A notable advantage of acid etching is its long-term and flexible design characteristics, especially when applied to stainless steel.

Topson Stainless Steel is a global leader when clients seek high-quality acid-etched stainless steel solutions. Their etched metal sheets are designed explicitly in high functional terms as well as high artistic appeal, with application across various sectors including hospitality, urban structure, and infrastructural design.