In modern industrial design and daily life, stainless steel, with its excellent corrosion resistance, high strength and modern feel, has become one of the most widely used materials.

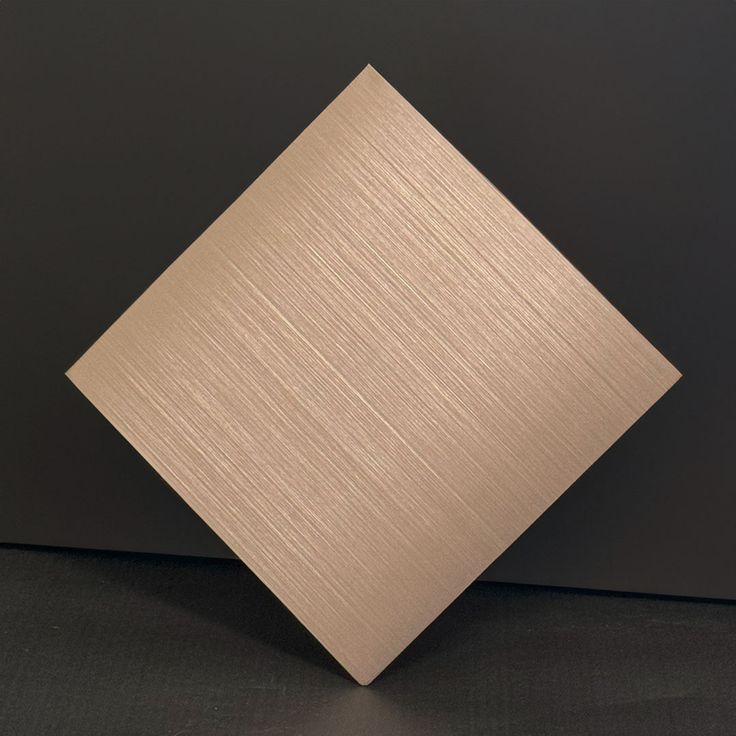

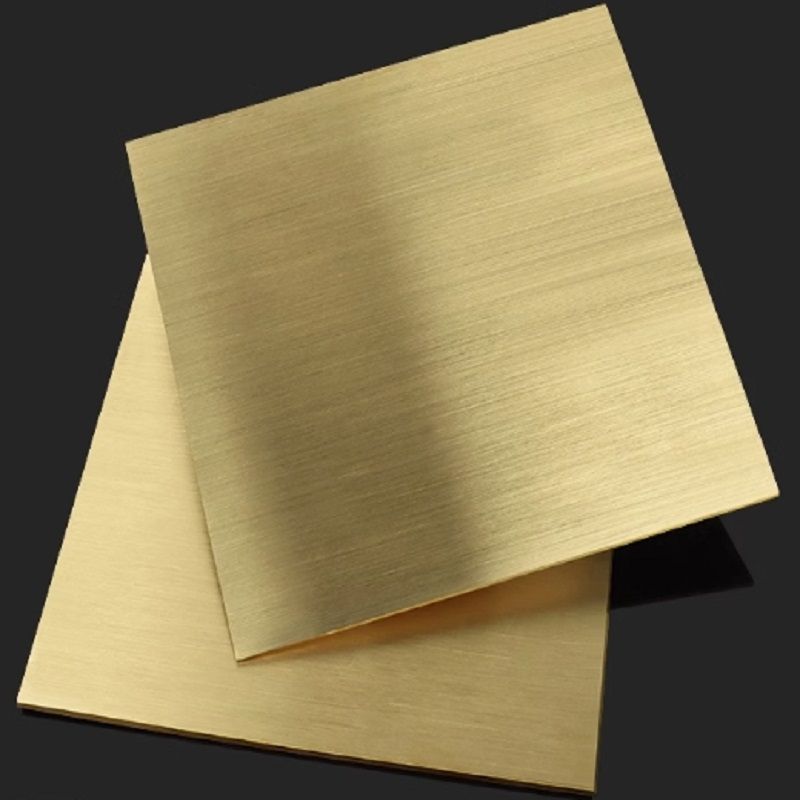

Stainless steel finish is key to conveying quality and shaping style. Hairline/Brushed, with its unique texture, delicate feel, and exceptional practicality, has become an important means of enhancing the quality and application value of metal products.

What Is Hairline/Brushed?

Hairline/Brushed is a surface treatment technique that creates linear patterns on metal surfaces through physical grinding. The core principle is to use abrasive materials (such as abrasive belts, scouring pads, nylon wheels, etc.) to rub the metal workpiece in a directional and uniform manner, removing the original shiny surface and creating a series of fine linear patterns with a silky luster.

The Core Processing of Hairline/Brushed

1.Pre-treatment

Cleaning and degreasing: Thoroughly remove the oil, dust and oxides on the surface of the metal plate, which is the primary prerequisite for ensuring uniform and consistent subsequent hairline/brushed effects.

2.Brushing

● This is the most critical step. Use specialized hairlineequipment (such as a brushing machine or belt sander) or manually to keep the abrasive material moving at a constant speed in a fixed direction.

● Choosing abrasive media: Choose abrasive materials (such as silicon carbide belts or nylon grinding wheels) and grit based on the desired effect. A higher grit number results in finer abrasive particles and a more refined grain; a lower grit number results in a coarser grain.

● Controlling direction and pressure: Maintaining steady downward pressure and consistent movement direction is key to creating a continuous, clear, and smooth, ripple-free surface.

3.Post-treatment

Washing: Remove all metal debris and abrasive residue from the surface.

Common Similar Texture Processes

Hairline process is a large family. By changing the grinding method, tools and paths, a variety of completely different texture effects can be derived:

● Hairline/brushed:The most common type. The texture is straight, like long hair, delicate and flowing, giving people a simple and modern visual experience.

● Vibration:The surface texture is irregular, dotted or messy. It is usually obtained by irregular grinding with a nylon wheel.

● Cross Hairline:On the basis of straight wire, another drawing is done along the opposite or specific angle to form a regular cross-net pattern.

● Satin:Similar to fine straight silk, but usually processed with finer abrasives (high mesh) or specific media, the surface texture is denser, the glossiness is slightly higher, the touch is as smooth as silk, and the texture is extremely high-end.

The Advantages:Why Choose Hairline/Brushed?

Improve aesthetics and texture: Transform industrial metal materials into artistic surfaces with soft luster and high-grade texture, significantly improving the appearance and visual value of the product.

Enhanced durability and practicality: The brushed surface resists fingerprints, scratches and stains, making it easy to maintain and clean.

Provide rich design diversity: different brushed textures can provide designers with a variety of choices to meet the needs of different styles from simple modern to light luxury industrial.

The Applications of Hairline/Brushed Finish Stainless Steel

Household appliances: high-end refrigerators, range hoods, ovens, and dishwasher panels, perfectly meeting the kitchen’s need for anti-oil and grease protection.

Building decoration: elevator car interior, door and window edging, interior and exterior decorative panels, stair handrails, signs and signs.

Daily hardware: watch straps, pens, high-end tableware.

Conclusion

Hairline/Brushed is more than just a simple surface treatment; it bridges function and aesthetics, industrialization and artistry. Through precisely controlled grinding, it transforms the coldness of metal into a texture rich with emotion, giving the product greater vitality and market competitiveness. Whether due to its unique practical advantages or its rich artistic expression, wire drawing continues to play an indispensable role in high-end manufacturing, continuously defining the exquisite connotations of modern products.